50 Expert Warehouse Design and Layout Ideas and Tips

Table Of Content

Designate dynamic zones within the warehouse where space allocation can be adjusted on demand. This adaptive approach ensures optimal space utilization, prevents overstocking or underutilization, and maintains operational efficiency during periods of change. In the holistic journey of warehouse design, Step 8 stands as a testament to the profound belief that the well-being of the workforce is paramount.

Improved supply chain

This non-stop rhythm ensures that customer orders are fulfilled promptly, contributing to heightened customer satisfaction. Designed to work alongside warehouse staff, these robots augment operational capacity, undertaking tasks such as material transport, order picking, and inventory replenishment. The result is a synchronized dance of efficiency, where human skills and robotic precision converge. As we delve into the advanced realm of warehouse layout optimization, the spotlight turns to Automation Integration—a paradigm shift that redefines efficiency, precision, and spatial utilization. In this expansive exploration, we navigate through a tapestry of cutting-edge technologies poised to revolutionize warehouse operations. In the grand tapestry of warehouse design, Step 9 stands as the guardian of adaptability and resilience.

Highlight products

AI and Digital Twins Revolutionize 2024 Warehouse Operations - EPAM

AI and Digital Twins Revolutionize 2024 Warehouse Operations.

Posted: Mon, 11 Mar 2024 07:00:00 GMT [source]

If all you need is a simple 2D architectural design, Draft it Free is a great choice. And if you decide you need more advanced features, you can always upgrade to their Plus, Pro, or Architectural plan. Human workers collaborate with robots, guided by visual cues and supported by aerial insights. This collaboration ensures that each order picking task is executed with efficiency, allowing human workers to focus on higher-value activities within the warehouse.

Provide your warehouse workers with detailed maps and pick routes

In today’s competitive business landscape, warehouses are the backbone of many operations. A great warehouse layout design can increase efficiency, reduce costs, and ensure safety. Selecting the most suitable warehouse layout design for your facility is crucial to ensure the optimal utilization of resources. The best way to make sure that this task does not get overwhelming for you is to consider the factors mentioned in this article.

Designating specific pathways for pedestrians ensures that they have dedicated routes, minimizing the risk of collisions and enhancing overall safety. When integrating technology, it’s essential to choose scalable and adaptable solutions. Technology evolves rapidly, and a warehouse’s technological infrastructure should be capable of accommodating future advancements.

Plan for Growth and Adaptability

Each of these questions should be answered before you draft warehouse designs. Warehouse design and layout are dynamic processes that require careful consideration of space, technology, and operational needs. By understanding the various types and implementing best practices, warehouses can optimize layouts for increased efficiency, safety, and adaptability. Every company wants to improve productivity and speed up order fulfillment without sacrificing quality.

With goods arranged in this way, it is easier for workers to locate the items they need quickly, thus saving time and effort. Wasted time, compounding over the course of several days or weeks can lead to you being behind on orders, and thus, unhappy customers. It also includes conducting regular audits to make sure that items are in their proper place and that the shelves are properly stocked with inventory.

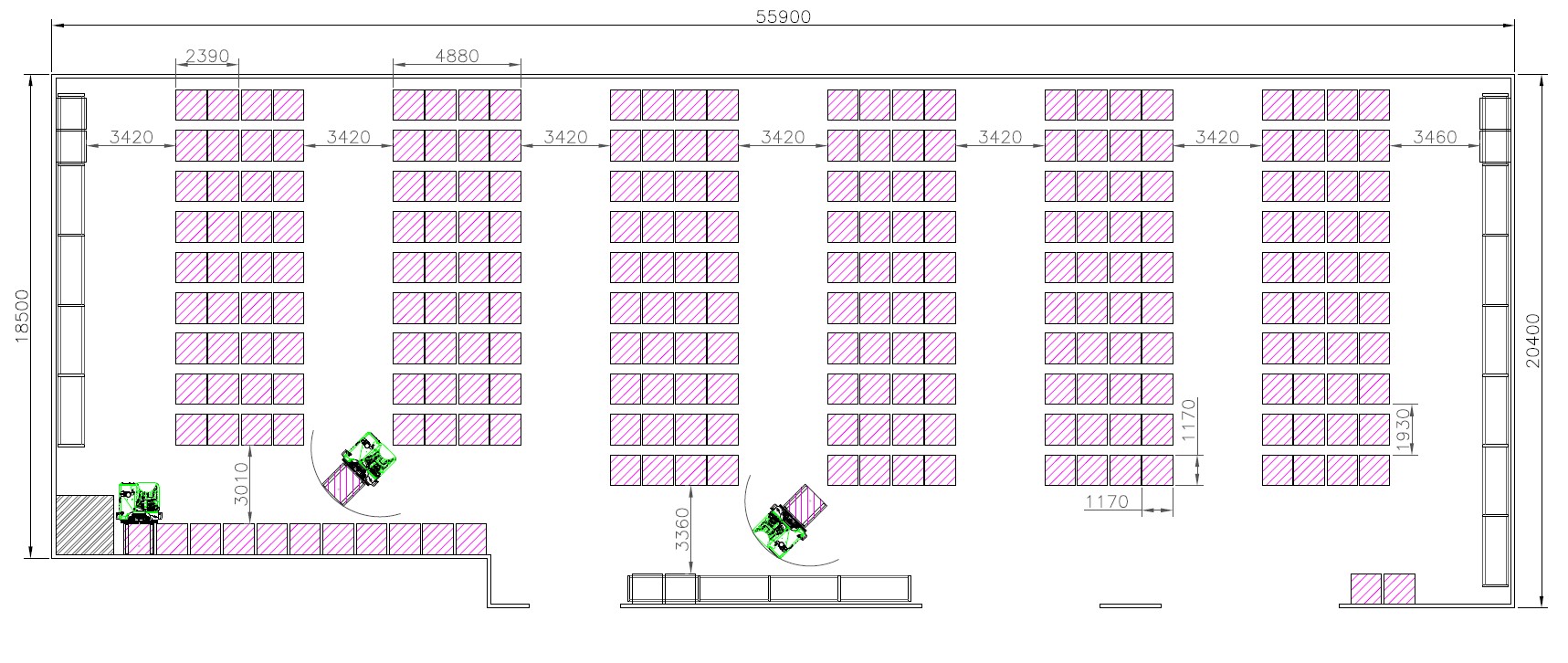

Step 4: Use Efficient Traffic Flow Strategies

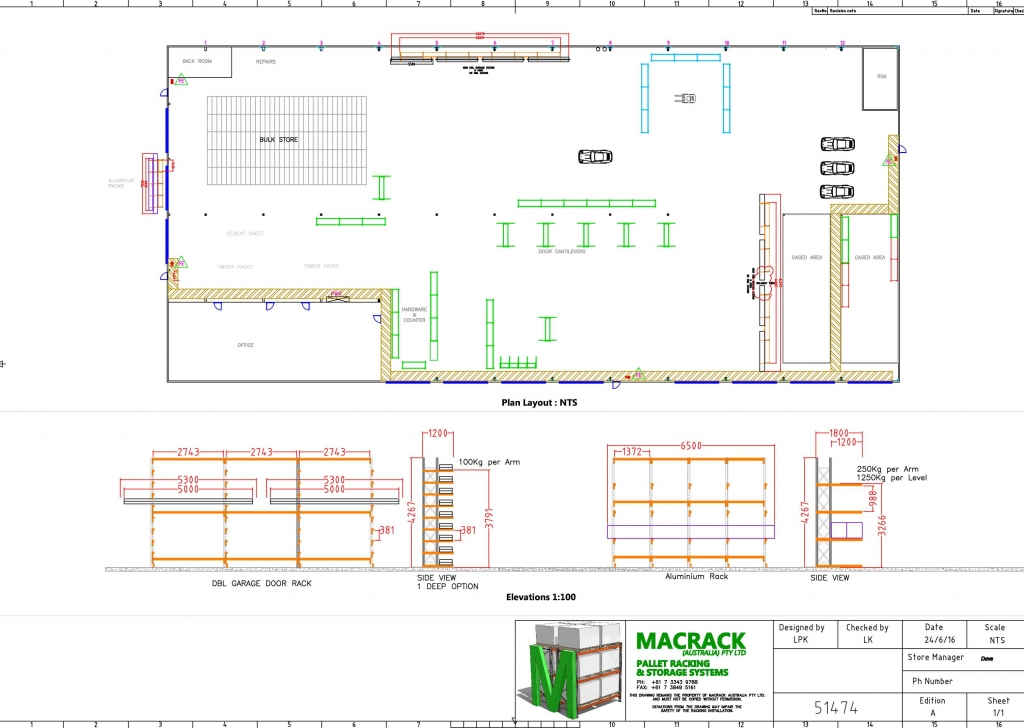

Incorporating tall racking systems is a fundamental aspect of maximizing vertical space. These systems are designed to efficiently store goods at varying heights, often reaching several meters. Tall racks are particularly advantageous for storing lightweight and compact items, making them ideal for facilities dealing with a diverse product catalog. This configuration allows for denser racking systems and higher vertical storage, optimizing the overall capacity of the warehouse.

What to Consider When Designing Your Warehouse Layout

In addition, with this option the process of loading and unloading goods is totally independent of the work cycle of the warehouse. Along with optimizing storage costs, you don’t have to worry about hiring staff to manage demand, design, and optimize picking workflows, or worry about investing in technology and equipment. Decide how you’ll create an efficient workflow before you establish workflows, productivity zones, inventory storage areas, and equipment storage. Your picking team will understand your current warehouse layout better than anyone because they’re constantly moving around the entire space. Be sure to work with them to identify opportunities to create better fulfillment workflows that eliminates headaches, confusion, and human error during the entire process. Reorganizing routes or zones, or even an entire warehouse, can seem like a daunting and time-consuming project.

A resource center is also available for the user to connect in case of any problem working on the tool. Grab a template today or choose one from Templates Community and customization as per your taste. Your warehouse layout should have easy access to all the products and areas of the facility. Ready to deliver products should be picked without moving the other products and packages every time.

In this article, we will learn about the advantages of optimising warehouse layout, which will help you run your warehouse as efficiently as possible while saving you many procedures, time, and costs. Your warehouse layout design may be influenced by various equipment types, such as lifting and packing equipment, pallet racks, or conveyors. You can assess and build the best layout in accordance with your requirements and increase the efficiency of your business by determining the equipment required. Utilizing the warehouse area to its full potential can increase operating efficiency, save travel time, and improve inventory visibility. The most space possible must be set aside for storage and inventory processing.

Light-duty shelving works well with stacked parts bins (discussed below) for stocking small items and assembly parts. Before using forklifts in your warehouse operation, thoroughly review all manufacturer recommendations for the machinery you procure. Additionally, before operating a forklift, familiarize yourself with OSHA’s rules regarding forklift use and follow all mandated forklift training requirements. There will be instances when the highest load height isn’t uniform throughout the warehouse area.

Cube-shaped or humanoid? How to pick the best warehouse robots - TechHQ

Cube-shaped or humanoid? How to pick the best warehouse robots.

Posted: Wed, 15 Nov 2023 08:00:00 GMT [source]

One of the best (and worst) feelings as a warehouse manager is optimizing your warehouse design and warehouse layout to find that you don’t actually need all the space you’re paying for. If it’s possible, walk through your layout in the space before you build your design. Tape or mark out where everything will go in your empty warehouse space, and have a few employees walk through workflows.

The successful integration of technology goes hand in hand with effective change management. As processes shift from manual to automated, employees need to be trained to operate and collaborate with the technology seamlessly. Change management strategies foster a positive transition and ensure that the workforce embraces technological enhancements. Robotic picking systems, equipped with advanced vision systems and robotic arms, automate the picking process. These robots can navigate through aisles, identify products, and pick them with remarkable accuracy. Robotic pickers not only expedite the order fulfillment process but also mitigate the risk of errors.

Comments

Post a Comment